BELFAST: ITS TRADE AND COMMERCE.

By Alec Wilson.

-- -- -- -- --

THE rise of Belfast into its present position as the "Commercial Capital" of Ireland has been so rapid and remarkable, that it deserves to be again emphasized, though it has been already mentioned in the preceding article. A century ago, Belfast was hardly more than a village at the end of a tidal estuary, navigable only by vessels up to 300 tons, which had to work slowly along a difficult stream between banks of "slob." There were many ports which looked more suitable for a considerable over-seas traffic; and, in fact, it was not until the advance of mechanical knowledge had produced the power-loom and the dredger that Belfast's real history began. It then became evident that the central position in which the city stands as regards the North of Ireland had marked it out as the depot for Ulster; but the business aptitude of Belfastmen took their trade far beyond the comparatively small duties of supplying their own neighbourhood : and to-day, the linen, ships, ropes, tobacco, and many other products of Belfast are famous the world over.

Since 1841 a straight channel has been cut for a length of four miles, a work of great importance, giving a waterway of 300 feet wide, with a present depth of 28 feet at high water. There are a large number of steam cranes, lifting from 2 to 100 tons, the latter being erected alongside the Alexandra Dock. This dock is 825 feet long and 85 feet wide at the entrance; it is thus among the largest in the Kingdom; but a still larger one is projected. The present area of the docks and basins is about 136 acres, and considerable extensions are in contemplation, to give proper accommodation to the many traders who find the existing quayage too congested for their requirements.

The Belfast Harbour Commissioners are spending large sums of money in improving the harbour and docks.

The MUSGRAVE CHANNEL, which will run from the north end of the East Twin Island, constitutes practically a duplication of the Victoria Channel, and will be about 1½, mile long and 300 feet wide at the bottom, with a depth of 17 feet at low water. This depth can be increased at will, as the trade demands.

Three large wooden jetties are being constructed in this channel for the convenience of the shipbuilding trade, and the provision of these jetties is expected to considerably relieve the congestion in the main harbour.

Parliamentary powers have been procured for the construction of a large tidal dock of 14 acres at the south end of the Musgrave Channel, as well as of a graving dock, which, when built, will be the largest and most complete in the world, and it is expected that work will shortly be commenced on one or both of these undertakings.

Sufficient has been said to demonstrate that the Belfast Harbour Commissioners are fully alive to the importance of keeping pace with the times.

The revenues collected by the Customs authorities now approach £3,000,000, being the third largest in amount of the ports in the United Kingdom, and only exceeded by London and Liverpool. The following tables illustrate the growth of the shipping trade of Belfast:

| Tonnage registered at the Port. | Tonnage cleared from the Port | |||||

|---|---|---|---|---|---|---|

| Year. | Vessels. | Tonnage. | Vessels. | Tonnage. | ||

| 1840 | 355 | 45,632 | 3,323 | 361,473 | ||

| 1850 | 463 | 74.770 | 4,490 | 624,113 | ||

| 1860 | 508 | 74,049 | 6,658 | 885,413 | ||

| 1870 | 462 | 62,653 | 8,303 | 1,616,908 | ||

| 1880 | 399 | 76,386 | 7,965 | 1,225,566 | ||

| 1890 | 293 | 125,632 | 8,050 | 1,840,666 | ||

| 1900 | 210 | 147,575 | 8,318 | 2,325,936 | ||

The Corporation of Belfast have for some time adopted the policy of taking over, when possible, the various public services under their own management. One of the most important of these is the GAS-WORKS; and the enterprising way in which these have been managed will be obvious to anyone who visits the magnificent range of buildings on the Ormeau Road. During the last twenty-five years the consumption of gas increased so rapidly that the congestion in the works became very great; the remedy adopted was the erection of plant for the manufacture of carburetted water-gas. This has proved a most satisfactory means of cheapening the gas as well as of producing it in large quantities; no less than a million cubic feet per hour being delivered during the busiest time of the evening. To cope with this output, the six gas-holders are, of course, of large size, the largest of them containing over 2½ million cubic feet. The cost to the consumer is on a sliding scale, ranging up to 2/3 per 1,000 cubic feet.

The Corporation are now organizing a TECHNICAL INSTITUTE, which deserves a short description.

The city has a grant of £10,000 a year, in aid of technical instruction, from the new Department of Agriculture and Technical Instruction. This sum is administered by the Library and Technical Instruction Committee of the Corporation. In 1900 it was decided to build a Technical Institute, and a site was secured having an area of some 5,450 square yards. Plans were prepared, and a Principal appointed. After careful inquiry, it was considered that the proposals were inadequate for the prospective needs of the city, and the plans were accordingly enlarged. Tenders have now been accepted for the erection of the building, the contract price being £81,000. The building will be completed about the year 1905. In order to avoid duplication of classes, the committee held a number of conferences during 1901 with the various schools then providing evening instruction in Science, Art, and Technology, resulting in these bodies handing over their work to the city. This has enabled the Institute to formulate a homogeneous scheme of instruction, to secure an efficient organization, and to provide against waste of funds or of teaching energy.

The first evening session opened on the 30th September, 1901. That the efforts of the committee have met with a gratifying response is shown by the fact that the number of tickets issued up to date (May 1902) for the various courses of instruction is 4,290: in addition, 5,220 tickets have been issued for single lectures The work is spread over a large area, there being, in addition to the four central buildings, six branches in outlying parts of the city. There is a staff of about 100 teachers and assistants.

It is to be hoped that the Corporation will, before long, get the TRAMWAYS under their control, as until then there seems no chance of establishing any form of mechanical traction, and the city has to put up with the now antiquated horse-tram.

The following tables are extracted from the Report of the Belfast Harbour Commissioners for 1901, but it is to be noted that 190T was a year of general depression, and that many of the figures are consequently lower than usual :

| IMPORTS. | EXPORTS. | ||||

| Ale and Beer | 6,111 | tons. | Aerated Waters | 9,721 | tons |

| Anchors, etc. | 1,185 | " " | Apples and Pears | 1,153 | " " |

| Barley (raw) | 19,620 | " " | Bacon | 9,382 | " " |

| Bleaching Powder | 2,800 | " " | Butter | 3,261 | " " |

| Bottles | 6,134 | " " | Candles | 550 | " " |

| Bran | 26,546 | " " | Cattle | 109,613 | " " |

| Cement | 23,656 | " " | Coal | 11,588 | " " |

| Coal | 1,164,641 | " " | Cordage | 6,297 | " " |

| Coke | 6,219 | " " | Cotton Goods | 5,495 | " " |

| Cotton Goods | 12,010 | " " | Cotton (raw) | 23,028 | " " |

| Deals | 34,905 | loads | Eggs | 12.254 | " " |

| Dyestuffs | 1,801 | tons. | Felt | 13,868 | " " |

| Fish | 2,616 | " " | Fowl | 2,821 | " " |

| Flax | 21,716 | " " | Hams | 2,585 | " " |

| Flaxseed | 1,640 | " " | Hay and Straw | 16,359 | " " |

| Flooring Boards | 17,415 | loads | Hides and Skins | 2,078 | " " |

| Flour | 106,100 | tons. | Horses, Mules, and Asses | 7,771 | " " |

| Grains | 8,634 | " " | Indian Corn and Meal | 32,671 | " " |

| Hemp | 11,442 | " " | Iron Ore | 41,964 | " " |

| Indian Corn | 202,786 | " " | Iron (scrap) | 16,100 | " " |

| Iron (cast and wrought) | 54,202 | " " | Lard | 3,558 | " " |

| Lard | 2,731 | " " | Linen | 40,609 | " " |

| Linseed Cake | 8,896 | " " | Machinery | 6,078 | " " |

| Machinery | 7,159 | " " | Manure (artificial) | 9,721 | " " |

| Oil (Petroleum and Paraffin) | 33,298 | " " | Meal, etc. | 8,735 | " " |

| Onions | 5,690 | " " | Meat | 2,007 | " " |

| Paper | 7,792 | " " | Mussels | 1,436 | " " |

| Phosphates | 8,645 | " " | Oats | 2,427 | " " |

| Porter | 11,084 | " " | Oil (Petroleum and Paraffin) | 14,202 | " " |

| Rivets | 3,432 | " " | Pigs | 70,602 | " " |

| Rosin | 4,153 | " " | Pork | 1,195 | " " |

| Rye | 14,796 | " " | Potatoes | 25,958 | " " |

| Sacks, etc. | 2,773 | " " | Rags | 1,335 | " " |

| Seed (Grass, etc.) | 2,260 | " " | Ropes | 2,616 | " " |

| Sheep | 16,560 | " " | Salt (crushed) | 4,622 | " " |

| Shoes | 2,410 | " " | Sand (moulding) | 10,717 | " " |

| Slates and Slabs | 6,888 | " " | Seed (Grass, etc.) | 15,394 | " " |

| Soda (Crystals, etc.) | 8,081 | " " | Sheep | 31,385 | " " |

| Spokes | 20,350 | " " | Thread | 1,056 | " " |

| Steel | 63,534 | " " | Tobacco | 2,493 | " " |

| Stone (paving and building | 24,463 | " " | Whiskey | 29,586 | " " |

| Tiles | 9,772 | " " | Yarn (Linen) | 7,973 | " " |

| Wheat | 12,996 | " " | Yeast | 2,630 | " " |

TRADES AND INDUSTRIES OF THE CITY.

IN the limited space at our disposal, it is obviously impossible to go fully into the details of every industry carried on in the North of Ireland, and it has been thought better to select a few representative firms, and describe them somewhat better than would otherwise have been possible. Ab una disce omnes. There are many firms whose factories and workshops are fully equal to those described here, but which have had to be omitted, either on the score of space or to avoid reduplication, and to prevent this account from becoming a mere list of names : it is therefore necessary to apologize to very many firms of the first repute, whose names have been left out as the result of adopting this method of illustrating our commerce. And here the compiler must offer his best thanks to the various firms who most kindly supplied the information upon which this article is based; also to the principal of the Technical Institute (Mr. F. C. Forth), to the Belfast Harbour Commissioners, and to the proprietors of the Belfast Directory for their kind permission to use their valuable statistics and information. We may now proceed to a brief account of the LINEN TRADE, the greatest of Ulster industries.

Linen and other textiles have for centuries formed a mainstay of Ulster; for so early as A.D. 1216 we find it stated by Macpherson that the linen manufacture was then in a flourishing condition, and in 1245 De Burgo, Earl of Ulster, had large parcels of linen woven for him at Ballylisnevan, now called Newtownards. Woollens, again, in the reign of Charles I. were exported to the value of £110,000 annually. Protection laws in England ruined this latter trade, but linen-weaving was revived on a large scale by the Huguenots after the Revocation of the Edict of Nantes. The real founder of the present great industry was one Crommelin, who settled at Lisburn in 1619, together with a few other men, who were induced to do so largely by the advantages offered by William III.

In 1711 a Board of Trustees was appointed to supervise and encourage Irish flax and hempen manufactures, who exercised a large influence on the trade for more than a century; among their duties were the examining and stamping of every piece of linen offered for sale, and also the granting of bounties and prevention of fraud. They kept a detailed record of the exports of linen and linen yarn. The following is taken partly from their tables :

| YEAR | EXPORTED. | YEAR. | EXPORTED. |

| 1690 | 300,000 yds. plain linen | 1780 | 18,746,902 yds. plain linen |

| 1720 | 2,400,000 | 1810 | 37,061,859 |

| 1750 | 1,200,000 | 1820 | 37,464,279 |

About the year 1828 mechanical methods began to be adopted, and the whole system was thereby remodelled, as will be evident from the fact that one girl can now attend to about 160 spindles, each producing daily twice the amount formerly spun by hand on a wheel. Next to the invention of machinery, the linen trade received its greatest impetus from the American Civil War, which destroyed the manufacture of cotton in the States, resulting in a boom in linen, which laid the foundation of several great fortunes; but the reaction was severe, affecting the linen merchants of Ulster for many years. During the last ten years there has been but little expansion, and, no doubt, the competition of cheap foreign goods has made itself felt. A curious feature of the linen trade is that so few of the firms engaged in it carry on more than one or two of the operations necessary for the production of the finished web. The most important of these processes are as follows : scutching, spinning, weaving, beetling, and bleaching. Several of the larger establishments, however, have every part of the manufacture of their linen under their own control. The following figures illustrate the more recent history of our staple industry :

| SPINNING MILLS. | POWER LOOM FACTORIES | |||

| Year | Spindles Employed | Spindles Unemployed | Total Spindles | Total Looms |

| 1883 | 816,334 | 58,454 | 874,788 | 21,779 |

| 1885 | 810,456 | 63,454 | 873,910 | 24,300 |

| 1887 | 803,026 | 40,564 | 843,590 | 25,300 |

| 1889 | 827,451 | 7,456 | 830,907 | 26,360 |

| 1891 | 827,451 | --- | 827,451 | 26.592 |

| 1893 | 837,642 | 9,000 | 846,642 | 28,233 |

| 1895 | 846,642 | --- | 846,642 | 28,764 |

| 1897 | 869,056 | --- | 869,056 | 31,484 |

| 1899 | 835,100 | --- | 835,100 | 31,484 |

| 1901 | 830,700 | --- | 830,700 | 31,484 |

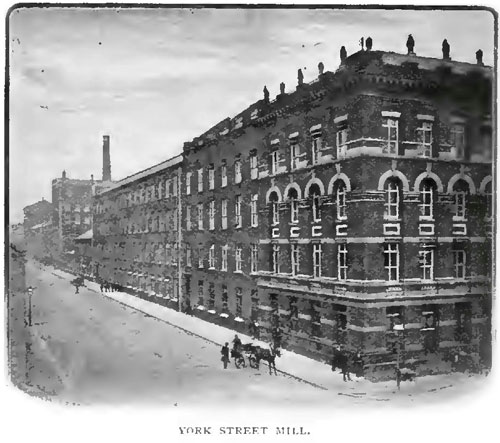

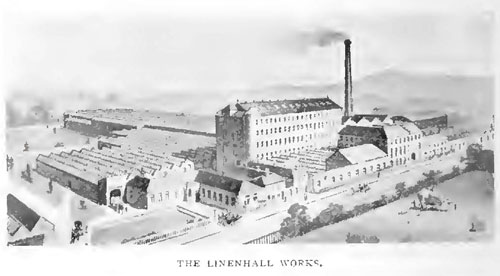

Having thus sketched the history of the Linen trade, a short description of a representative mill may be given. The YORK STREET FLAX SPINNING CO.'s concern is one of the largest and best-equipped of flax mills, and is one of the "sights" of Belfast; it is also the oldest of its kind, having been started in 1830. Since the foundation of the present company in 1864, the works have been greatly enlarged by the purchase of other premises, including a bleaching-green and a mill, and now all the operations necessary to convert the raw flax into the finished web are carried on. The visitor enters the main offices, and follows each stage of the manufacture as he makes the tour of the numerous buildings and rooms. A huge block is given over entirely to storing flax and stock linen, no less than six floors being required for the former. Technically, the raw flax becomes "line" after being hackled and dressed, the waste product being "tow." There is an unexpectedly great variety in the type and quality of flax, that of Belgian growth from Courtrai being the finest. It is better scutched than our Irish product, and there is no doubt that local flax leaves room for improvement in this respect. Quality depends also of course upon the soil, humidity, and the season. The next block is the preparing mill, where the raw flax is first treated; it is dressed by hand, the rough flax being drawn through combs to remove the dirt and particles of bark. This is a very dusty process, and was very unhealthy; but now a cowl is fixed in front of the comb before each man, communicating with a ventilator shaft, in which suction is kept up by means of a rotary fan, so that all the dust is instantly carried away. On this floor are also the hackling machines, and machines for cutting the fibre into the middle and two ends, thus making three qualities, suitable for different purposes. These are now dealt with by hand, and sorted into a number of qualities, which sorting requires a good deal of judgment, and is of great importance.

The first floor of this building is used for tow carding and preparing, the second and third for flax or "line" preparing, which includes "spreading," done by women who feed the "line" on to leather bands, and the machine produces the "sliver," which then goes to the "drawing" and "roving" machines. The east end communicates with the spinning-mill by a six-storey building, on three floors of which "rove" is stored on its way to the mill, and on the ground floor of which is the mechanics' shop.

We next come to the great spinning-rooms, 221 feet by 42 feet; three of the floors are wet spinning-rooms. The spinning machines are tended by women and girls; and one may remark, en passant, that not the least of the causes of Belfast's success as a manufacturing centre is, that its staple industries employ all the available members of a working-man's family. Above the spinning-room is the reeling-room, from which a wire tramway runs to the drying-loft over the boiler-house. Here are the reeling machines which take off the yarn on to reels, some of the product being sold in the form of hanks and some on reels. These go to the hand-loom weavers, of whom there are still a considerable number. On the Henry Street side are various blocks used as stores, offices, saleroom, etc., and containing lapping and measuring machines.

Leaving now the section known as the mill, we pass to the other half of the works, which is called the factory, consisting of preparing department and weaving sheds, containing about 1,000 damask and plain looms. Many other departments might be noted if space permitted; but the main driving-engines are of interest, as being among the few large beam-engines still in use. They have been, of course, modernized in various ways, and have proved themselves to be both reliable and economical. Next to the engine-house is the electrical plant, obtaining its power from the main shaft close by. The York Street Mill employs some 5,000 hands, of whom about half are women and girls, but not all of these are at headquarters, for there are several other establishments belonging to the firm, among them being the York Road Mill, the Muckamore Bleach-works, which last are most interesting, but too far from Belfast for the Association to inspect.

The next great industry of Belfast is, of course, Shipbuilding, carried on by two firms, Harland & Wolff, Ltd., and Workman, Clark & Co., Ltd., who turn out vessels of workmanship and design second to none, and whose rapid development is almost unprecedented.

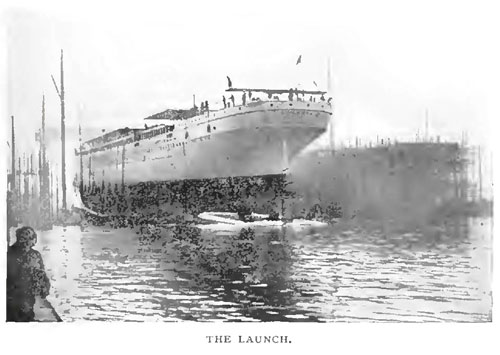

It is now over 50 years since the foundation of HARLAND AND WOLFF'S WORKS was laid, the nucleus being the Belfast Ironworks, which intended to begin the manufacture of iron in Belfast. Their purpose was defeated by the expense of importing coal; but the second part of the enterprise -- the ship-yard -- prospered, in spite of the handicap of importing both iron and coal. Hickson & Co. were the proprietors till 1858, when the late Sir Edward Harland, Bart., M.P., took over their business and that of the Belfast Shipbuilding Company. Since then the firm has been steadily progressing, and it now stands at the head of the shipbuilding trade of the world. From 1890 to 1894 it turned out the greatest tonnage of any concern in the Kingdom, and was only prevented from doing so in 1895 by the engineers' strike, which delayed the launching of several vessels. Last year the output exceeded their own previous world's record by about 10,000 tons, and created a new one.

Indeed, the growth of the "Queen's Island" during the last five years has been even more marked than its earlier achievements; and besides heading the tonnage list, they have made great additions to the various departments; the works, a short time ago, covering 120 acres, with every appliance of the latest type, some of the new tools being of the finest description : for instance, the three huge "gantries" are each 100 feet wide and 90 feet high, and are arranged to travel the whole length of the "slips." The "Oceanic" and "Celtic," the White Star monsters, and the largest vessels afloat, were built under one of them; in fact, the first was arranged expressly for the construction of the "Oceanic," no less than £20,000 having been spent on the slip and the gantry before her keel was laid.

During the last five years many ships of the largest size have been constructed; including, besides the two named, the "Cymric" (the largest vessel employed in the transport service to South Africa), "Afric," "Medic," "Persic," "Runic," "Suevic," and "Athenic," for the White Star Line; the "Statendam," "Rotterdam." "Ryndam," and "Noordam," for the Holland-America Line; the mail-boats "Briton," "Saxon," and " Walmer Castle," for the Union-Castle Line; the "New England" and "Commonwealth," for the Dominion Line; the "Minneapolis," "Minnehaha," and "Minnetonka," for the Atlantic Transport Line; and other large vessels for the Leyland, Bibby, and Warren Lines. A notable feature in these ships has been their steady increase in size, the average for the last two years being nearly 13,000 tons.

The firm have also carried out some important repairs and alterations; among others, the "Scot" and the "Auguste Victoria" were cut in two and lengthened some 60 feet. The P. & O. liner "China" was also rebuilt after being on the rocks at Perim for many months; but perhaps the heaviest job of this kind was the work to the "Paris," after she had been on The Manacles. She was temporarily strengthened at Milford, and then re-docked in Belfast, where her bottom was cut out and renewed, as in the case of the "China," but, in addition, the vessel was completely altered, and new machinery supplied at a total cost of about £250,000.

Although the firm built vessels for the Admiralty some years ago, and have recently constructed the engines for first-class battleships, Belfast has not built any of the latest warships; but it is hoped that, when the new graving-dock is ready, our premier shipbuilders will be entrusted with more work for the Government. Of course, however, the largest vessels they build are nearly twice the length and displacement of even the largest warships. They have now in hands the engines for H.M. SS. "Queen" and "King Edward VII." It is anticipated that the agreement which has recently been made with the Morgan Shipping Combine will give a still further impetus to the shipbuilding yards of Belfast.

The visitor to the works will begin with the main offices and the spacious drawing-office, where all plans and designs are prepared. These are naturally large, as ships of 600 feet to 700 feet are drawn to a scale of ¼ inch to a foot. Next will be een the large building containing the joiners' shop, saw-mill, plumbers' shop, etc. A noticeable feature of this department is the arrangement for disposing of saw-dust and cuttings. Communicating with each machine is a large galvanized tube, in which rotary fans maintain a powerful suction, thus delivering the waste to the boilers, where it is used as fuel. Close to this is the mould-loft, in which the scale drawings sent out from the office are reproduced full size, and very carefully checked in the process, for upon the accuracy of this work depends the construction of the ship. The lines are first drawn in chalk, and when verified are cut into boards which go to the platers' and other shops.

On the way to the plating-sheds will be seen several vessels in course of construction, and also the huge gantries already referred to. Near the slips are the shops where the plates and frames are worked into shape. Here are punching, planing, shearing, bending, boring, and rolling machines, furnaces for heating bars and plates, and heavy hydraulic presses for various purposes.

The engine-works will also be visited, commencing with the erecting-shop, where engines of all sizes, from the propelling machinery of liners to the smallest pumps, will be seen in all stages. The pattern and other shops will be inspected, and in the foundry will be seen castings of all shapes and sizes. The last department is the boiler-shop, a big shed fitted for building the heaviest marine boilers. The firm have not yet discovered a water-tube boiler suitable for merchant steamers, so most of the work on hands is of the well-tried Scotch type.

WORKMAN, CLARK & Co.'s yard has also had a notable history. Since their foundation, in 1879, it has grown from a small place of four acres, with a staff of 500 men, to its present position of fourth on the annual list of tonnage built in the United Kingdom, employing 5,000 hands and covering about 45 acres. They have built ships for the following among other companies : the Cunard, Allan, City, Harrison, Houlder, North-Deutscher Lloyd, Hamburg-American, and Lord lines, and the China Mutual, Ulster, West India and Pacific, and Ocean S.S. companies.

The following is the output of both firms since 1897 :

| Harland & Wolff. | Workman, Clark & Co. | ||||||

| Year. | Ships. | Tons. | I.H.P. | Ships. | Tons. | I.H.P. | |

| 1897 | 10 | 84,240 | 45,850 | 11 | 24,743 | 16,100 | |

| 1898 | 7 | 67,905 | 33,350 | 9 | 53,475 | 32,520 | |

| 1899 | 7 | 83,634 | 60,150 | 10 | 45,018 | 29,950 | |

| 1900 | 6 | 72,897 | 36,300 | 11 | 56,201 | 31,300 | |

| 1901 | 7 | 92,316 | 76,000 | 9 | 58,459 | 33,000 | |

| Total | 37 | 400,992 | 257,650 | 50 | 237,896 | 142,870 | |

The value of the ships built by these two firms amounts to over £7,000,000 during the last five years, and their combined wages lists averages from £15,000 to £18,000 weekly.

DISTILLERIES.

Among the large distilleries of Belfast, Messrs Dunville's holds a prominent place. The Royal Irish Distilleries were originally built in 1869-70, and rebuilt in 1876, after a tire which destroyed all the manufacturing part of the works. The buildings and plant are arranged for a weekly production of 40,000 gallons of whisky; and, in addition to the distilling part of the works, include extensive malthouses, grain-stores, drying-kilns, and excise warehouses. The best spot for a general view of the premises is from the top of the malt-houses, where there is an enormous tank, up to which water is pumped so as to command all parts of the works.

Distilling is carried on night and day, as the process is practically a continuous one. The by-products -- viz., grains, slumage, cake, etc. -- have a large sale for feeding cattle, enormous quantities being sold in the neighbourhood of Belfast.

The grain is delivered from the granary (the capacity of 5which is about 250,000 bushels) to the top of the malthouses by spiral conveyers and bands fitted with buckets; the wooden channels in which it travels are fitted with sliding doors, so that it can be delivered wherever required; it is then soaked in wooden vats until swollen, and the swollen grain passes on to the malting-floor, where it sprouts and becomes "malt." It is next dried, ground into "grist," and stored for use as required.

There are three immense "mash-tuns," in each of which about 2,000 bushels of malt are immersed at one time to undergo a churning process for some hours, until the whisky-producing qualities of the grain are exhausted. The fluid is stirred by fork-like arms, which revolve round the centre of the vat; it is then cooled and fermented in the tun-room, which contains 16 tuns of great size; the tuns are not filled more than two-thirds full, or they would overflow as soon as fermentation began. The liquor next passes to the three stills, through each of which it travels before the pure whisky is obtained; the spirit is discharged into vats, from which the casks are filled.

The water supply is drawn mainly from a boring of 400 feet, from which the water is pumped by forcing air to the bottom of the bore, after the manner of the American oil wells. Power is supplied by a modern compound high-speed engine, and there are four large Lancashire boilers, fitted with Green's economiser, everything being of the latest type.

In addition to the distillery proper, Messrs. Dunville have very large bonded stores, cooperage's, etc., in Alfred, Adelaide, and Callendar Streets.

A staff of no less than 24 Excise officials are daily engaged.

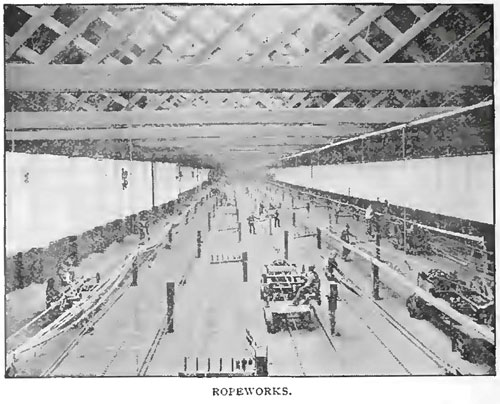

ROPE AND TWINE MANUFACTURE.

Another great business which no visitor to Belfast should miss seeing is the Belfast Ropeworks, which has now held for years an honourable place as the largest rope, cord, and twine manufactory in the world. Some idea of the importance of this trade to Belfast can be formed when it is stated that the output of cord and twine alone amounts to over 100 tons a week. Since its incorporation under the present management in 1876, the progress of the company has been most rapid. In 1879 there were under 100 employes; there are now 3,000, of whom a large proportion are women and girls. The consumption of twines and cords has greatly increased in recent years, and their titles are almost endless; but, as indicating merely the great variety of purposes for which they are used, the following may be named as a small representation : fishing lines and twines of all classes, adapted for floats, cod and conger lines, Manilla lobster twines, Italian salmon twines, deep-sea lead lines, log lines, boat lacing, garden and hammock lines, tobacco lines, tethers, hemp sealing twines, sisal lines, etc., etc.; and an inexhaustible variety of twines for packing, sewing, heddle, and harness, away to the fine and fancy articles used in shops and warehouses, and also employed for household requirements.

The company manufactures every description of rope and twine, from the largest cable for an Atlantic steamer down to the finest fishing line, of which 60 fathoms weigh only an ounce A prominent place among the cords is assigned to those used for window-sashes. In consequence of the great friction on them, they require to be made in plaiting machines to resist the wear and tear. The visitor will find this one of the most fascinating departments, and it is wonderful to see the almost sentient way in which the bobbins of thread interlace with each other while revolving round the central tube, up which passes the plaited cord to the bobbin on which it is wound. Another important department is that devoted to binder twine for reaping machines, and some of the most recent machinery has been specially introduced with a view to meet the increasing demand for this twine.

One of the few processes in which machinery has not yet ousted manual labour is the manufacture of nets, and several hundred girls are employed by the company in this department. The energy and vigour of the girls at this work are wonderful, and would delight the heart of an artist in figure painting.

The section in which the balling machines are operated is also most interesting, and the apartments set apart for this work furnish, perhaps, a better idea of the magnitude of the general business of the company than any other, as here the twine is being dealt with to fit it for the various markets, and the enormous scale on which this is done shows how extensive are the operations carried on.

Finally, the packing-rooms will be seen, looking to the visitor more like a dock-shed than the forwarding department of a single company.

TOBACCO MANUFACTURE.

Amongst the numerous industries of Belfast, the manufacture of tobacco occupies a leading place, and the factory of Messrs. GALLAHER, Limited, in York Street, is the largest in the United Kingdom. Messrs. Gallaher's old factory was in York Street, and this becoming too small for their increasing business, compelled them to build a more extensive factory. The floor space of the new building is about eleven acres, and is fireproof throughout. The frontage in Earl Street is 900 feet, and the main factory occupies 300 feet of this. One end of the factory, the main entrance and offices, face York Street, along which an elevation extends some 200 feet. The main gateway enters off York Street, between the offices and inner side of the factory, and leads into a glass-roofed yard, which gradually widens as it penetrates towards the centre of the establishment, where it broadens out into a roomy square, from which access is obtained to every part of the works, including the factory, boiler and engine house, despatch department, press cellar, offices, etc. On the ground floor is a dining-room and a waiting-room for the workers. The entrance to all the floors of the factory is made by a staircase of solid oak, beside which is a hydraulic hoist. The floors consist of heavy iron beams resting on columns; brick arches spring from the beams, and are covered with patent wooden flooring, and the principal rooms are laid with marble tarazzo. At the upper end of the factory are situated the carpenters' shops, bonded store, laboratories, etc. The press-room contains hundreds of hydraulic presses, which are constantly full of Irish roll tobacco, valued at over £75,000. The offices are approached from York Street through a fine porch and vestibule, leading into a large hall, with mosaic tiles, and having on either side private offices, waiting room', etc. Behind the main hall is the public office, which is lighted from the top by a large dome. The offices and factory are lighted by electricity, generated on the premises. Adjoining the factory is the private bonded store, a building six store) s high, having floor space of about 4½ acres. This building is fireproof, and is fitted up with hydraulic lifts, etc., giving every facility for working. Here are usually stored some 10,000 or 12,000 hogsheads of tobacco leaf. The firm turns out about 75 tons of manufactured tobacco weekly, millions of cigarettes, and a considerable quantity of snuff. It may be interesting to add that 25 years ago there were about twenty firms in Belfast engaged in the manufacture of tobacco. There are now only four, but Gallaher's alone does about four times the business that the whole twenty were doing at that time.

AERATED WATERS MANUFACTURE.

Among the products for which Belfast is famous, not the least important is the aerated water manufactured by several firms. A short account of Messrs. W. A. ROSS & SONS' works must stand for all. The first process is the manufacture of a syrup of sugar and water, made of the best cane sugar, mixed with certain flavouring essences, and filtered together into large crocks. The water is obtained from deep wells, tapping a bed of gravel remarkable for the purity of the water which it supplies; in fact, to this stratum is largely due the success of this industry.

The delivery-pipe of the well-pump is led into a large slate tank, glazed over, and fitted with glass stop-valves, etc., by which it communicates with a row of tanks containing the various flavouring liquids. On the floor below, the liquid is passed through the carbonating machines, in which carbonic acid gas, at 140 lbs. per square inch, is thoroughly mixed with and absorbed by the water. On the second floor are the bottling machines, which are most ingenious and interesting. With the majority of Messrs. Ross's machines the bottles are filled by a man on one side of the machine, and passed to another, who wires them; but there are also American "Crown" corking machines, which only require the services of one man, as they complete individually the whole process of filling, carbonating, and corking. Both corks and bottles are most carefully and thoroughly cleaned, the former by machinery, and the latter by hand, for no machine has yet been invented which can "see dirt" on a greasy bottle !

On the ground floor are the engine-room, the carbonic acid gas generator, the boiler-room, well-room, and the export packing-room. Leading out of the yard are cellars containing lime juice, cider, and hop bitters in bulk, and in another room lime juice, lemon syrup, and other cordials are made and bottled.

Ross's business was established in 1879, and, owing to the high standard of excellence, and the care taken to ensure cleanliness, they do a large trade, and have their full share of the exports of aerated waters from Belfast, which the Harbour Commissioners' report shows to exceed 10,000 tons annually. In fact, mineral waters from Belfast have won a first-class reputation in every part of the world -- a reputation shared alike by each of the six or eight leading firms in this business.

PRINTING.

In printing, Belfast has long held a high place, thanks to the standard set by the famous old firm of Marcus Ward & Company, of this city, which recently succumbed to the keen competition of younger establishments. One of these growing concerns was M'CAW, STEVENSON & ORR's, who, in 1899, purchased the good-will and stock of the older and now extinct firm.

The business includes almost every branch of artistic and ordinary printing and lithographing, as well as several specialities, such as "Glacier" window decoration, "Seccotine," which "sticks everything," and other patent preparations. A large amount of work is done in books, pamphlets, etc. (of which this handbook is an excellent sample), and quantities of show-cards, labels, and other advertising devices are produced. Diaries, scrap-books, birthday books, albums, pocket-books, Christmas, menu, and other cards, and every variety of stationery are a most interesting and important part of their work, in which they are carrying on the traditions of their predecessors. The visitor to the works will be struck, not only by the size of the establishment and the variety of its manufactures, but also by the excellence of its arrangements and the neatness and cleanliness of every part of the buildings, which cover some four of the seven acres in the firm's possession.

Five daily newspapers are printed in Belfast, the oldest of them being established for over 165 years. They have a large circulation in the Ulster district.

BISCUITS.

The manufacture of biscuits was introduced into Belfast over fifty years ago, and from a small beginning it has developed into a considerable industry. The trade has been practically in the hands of MARSH & COMPANY, and the fine pile of buildings in Donegall Street is a striking testimonial to the firm's success. The biscuit trade has provided a wide field of operations for the inventive engineer, and very frequently improved apparatus is introduced, until, at the present moment, the machinery in use by the leading manufacturers has reached a state of perfection almost human in its operations and results.

Marsh's factory is supplied with every modern contrivance for manufacturing biscuits and cakes, from the standard cutting machine to the intricate appliance for the production of "wafers." Over five hundred workers are employed. The trade is extensive, and the firm can compete successfully with English manufacturers for a share of their trade, while the Colonies account for a fair quantity. A reference to the Harbour Commissioners' reports for the last few years will show that the exports of biscuits from Belfast are usually equal to, and in many cases exceed, the imports : a remarkable fact, when it is remembered that our port is in daily contact with the " Land of Cakes " !

ALUMINIUM.

THE BRITISH ALUMINIUM CO. carry on an important industry at Larne, where the "Bayer" process is at work, separating alumina from the various impurities contained in a kind of clay known as bauxite,which is found abundantly in County Antrim. The bauxite is first ground to quarter-inch cubes, and is then calcined to destroy any organic matter contained in it. The calciner is an iron tube, revolving at a slight inclination, which delivers the roasted ore through a cooling tube to a second mill, where it is ground s'ill finer. The ground bauxite is treated with a strong solution of caustic soda, under steam pressure of loo lbs. per square inch, forming a soluble compound called aluminate of soda, the impurities remaining insoluble; the mixture of aluminate and caustic soda having remained in the pressure chambers or "kiers" for about seven hours, a cock is opened, and the pressure in the " kiers " blows the mass up to the filter-presses at the top of the building. The aluminate is now carefully filtered twice, to ensure the alumina being free from iron, silica, etc., the residue from this process being waste product.

The separation of the hydrate of alumina from the soda is effected by the addition of excess of hydrate of alumina itself, and by constant stirring in large tanks provided with agitators. This process takes about thirty-six hours, when the agitators are stopped, and the hydrate settles to the bottom. The hydrate is next pumped through filter-presses, and thoroughly washed, to remove the last traces of soda, and dried by forcing compressed air through the cakes which it now forms. The dried hydrate is next calcined, to drive off the water, and is then in the form of anhydrous alumina. This product is very liable to take up water again, so it is heated to about 2,000 degrees Fahr., which causes it to crystallize, and leaves it ready for packing.

This process is only the first step in the manufacture of aluminium, the pure alumina being sent to the Company's factory at Foyers, near Inverness, where the electric reduction of metallic aluminium from this product is performed.

THREAD MANUFACTURE.

One of the most important enterprises in the neighbour-hood of Belfast is the thread works owned by WILLIAM BARBOUR & SONS, Ltd., at Hilden, near Lisburn. Founded on a very small scale about 115 years ago, they have gradually grown in extent, until the firm now employ upwards of 5,000 hands, and control branch establishments of large size in America an.d Germany. The early history of the business is interesting as a type of other Ulster enterprises. Mr. Barbour (great-grandfather of the present representatives of the family) used to come over from Scotland to purchase the yarn then spun in the cottages in and near Lisburn; it occurred to him that it would be better to manufacture his thread, etc., on the spot, instead of bringing it first to Scotland. His son, the late William Barbour, carried on and enlarged the business; and as each new improvement was invented, he adopted it at Hilden, until he had a complete thread-making, spinning, dyeing, and bleaching works. The present output amounts to no less than 5,200 tons of single and twisted threads and yarns annually, and the wages paid total up to some £10,000 a month. The firm are now the largest manufacturers of linen thread in the world, and they produce an immense variety of work. The following are merely a few of the purposes to which their threads are applied : tailors' threads, boot and shoe threads, sole sewing and wax machine threads, carpet threads, bookbinders' threads, flourishing threads in all colours for embroidery, crewel-work, etc., netting twines and threads, gilling threads, upholsterers' and mattress twine, seaming and roping twines, Dutch twine, white twine, parcelling and packing twines, etc., etc.

The Barbours also make a great quantity of netting in all sizes, from sardine to sturgeon nets, and their machinery is of a new type, producing an excellent quality of net, which has taken honours at several fishery and other exhibitions. One of the pleasantest features of Hilden is the interest taken in the workers, many of whom live in the 350 houses surrounding the mill, and constituting quite a large village. There is a school attended by 800 children, a reading-room, and a dining-room, where hot meals are served at cost price.

OTHER INDUSTRIES.

In bringing this short account to a close, it will, perhaps, be well to mention some of the other manufactures and industries carried on in the Belfast district which have been omitted from lack of space. Engineering in various branches is carried on by several firms, of which the largest devote most of their attention to specialities, such as flax-spinning and weaving machinery, tobacco-making plant, mill engines, and machinery used in the manufacture of tea. Salt is mined on a considerable scale at Carrickfergus, where there are extensive deposits. The building trade is also of importance, with its allied businesses of brick-making and the importing and working of timber of all descriptions, both of which are the means of employing a great number of men. Curing provisions has long been a principal industry, and Belfast hams and sides of bacon are well known. Ice-curing and cold storage are engaged in by several firms during the summer. An extensive trade is done in grain, both home and foreign, in the milling of flour and barley, and in the manufacture of starch. Hats, boots and shoes, nails, matches, carriages, bottles, roofing and other felts, artificial manures, leather, beer, and furniture of all kinds, ornamental ironwork, stoves, stable fittings, and other specialities in iron, are among the minor manufactures, and the list is by no means exhausted. Enough, however, has been said to give a general idea of the extent and variety of the commerce of our northern capital.